Efficient

Directly from pallet to pallet

Efficient

Directly from pallet to pallet

Flexible

Grips almost every SKU

Flexible

Grips almost every SKU

Scalable

Individual design with expansion of robots and parking spaces

Scalable

Individual design with expansion of robots and parking spaces

Compact

Low space requirement due to multifunctional use of space in the material flow

Compact

Low space requirement due to multifunctional use of space in the material flow

The GenesysLineCompact system is an efficient solution for automated picking. It processes unmixed mono-pallets precisely into customer-specific mixed pallets ready for dispatch.

The GenesysLineCompact is supplied with unmixed mono-pallets via the specially designed incoming goods lane, which also serves as a buffer zone. This intelligent solution ensures a smooth material flow and optimised process control. Our specially developed kinematics move one after the other to predetermined pallet locations and gently pick up the corresponding SKUs one after the other with our patented gripper until the desired mixed pallet has been created. The finished mixed pallets are then discharged via the outgoing goods lane and can be immediately wrapped and made ready for dispatch at the customer's request.

- Unlimited product range: from small and light (L: 100 mm x W: 100 mm x H: 50 mm; 0.5 kg) to large and heavy (L: 1200 mm x W: 600 mm x H: 450 mm; 55 kg) without retooling

- High performance: Efficient work processes enable high throughput rates

- Individually adapted to your requirements: System configuration is determined according to throughput volume and picking duration

- Simple operation: Intuitive order management and low training requirements

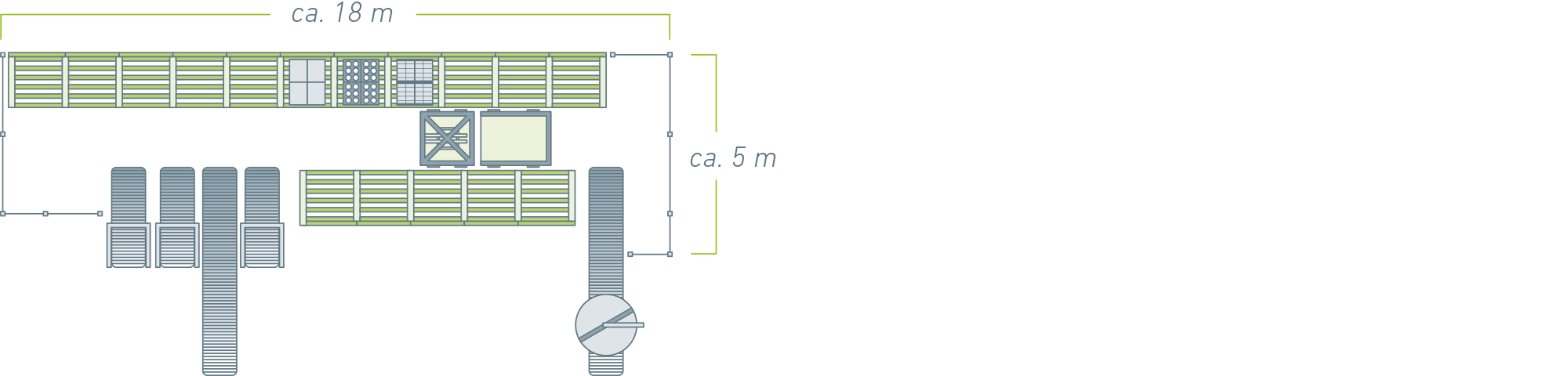

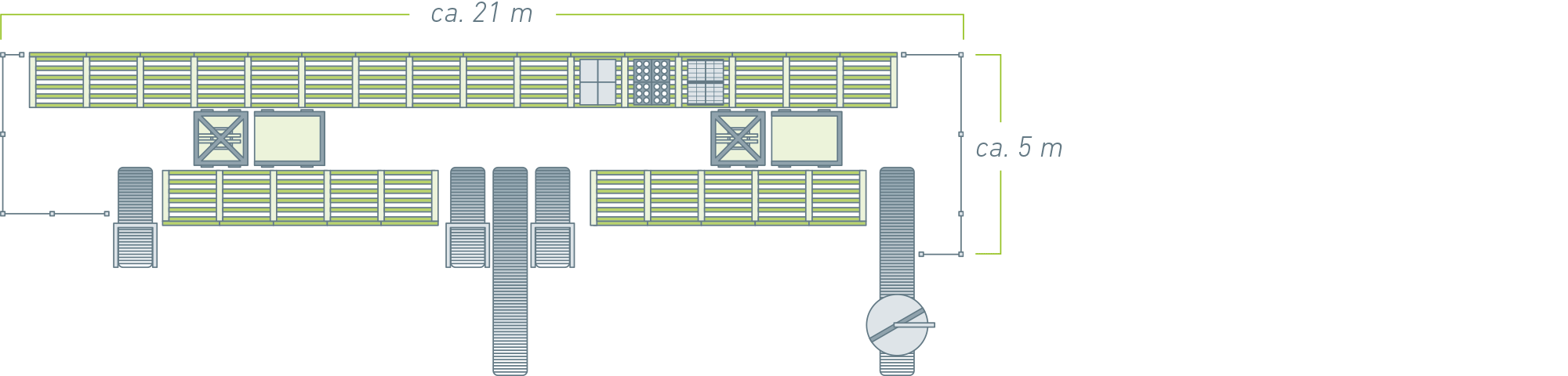

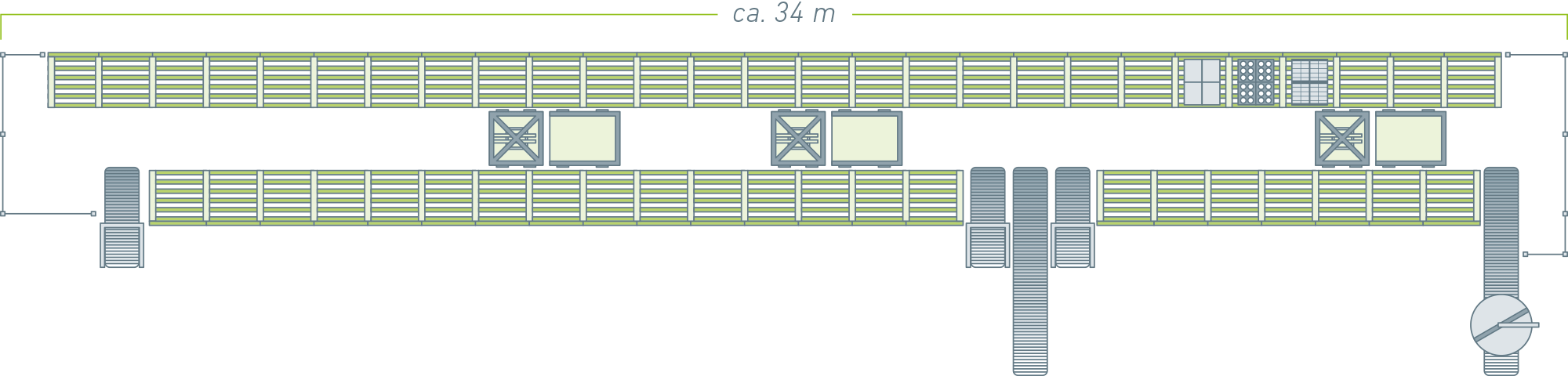

Depending on your specific requirements, the number of pallet spaces and the number of robots can be freely configured. This enables you to achieve optimum system performance, with which your SKUs can be picked automatically in the time available. The number of pallet spaces allows you to vary the quantity of items that are processed by the system and placed on the target pallets.

Analysis

We analyze your order data, the SKUs to be handled and your individual process requirements.

Concept

Together we will develop a customized concept for your GenesysLineCompact system, tailored to your needs.

Simulation

We use a digital twin to simulate the picking process in order to ensure efficiency and feasibility.

System concept, offer and service description:

Based on the previous steps, we create an optimal concept for your GenesysLineCompact system that perfectly meets your requirements.